Email for consultation

and quotation

Telephone quotation request

and consultation.

(+86)-755-2828-2209

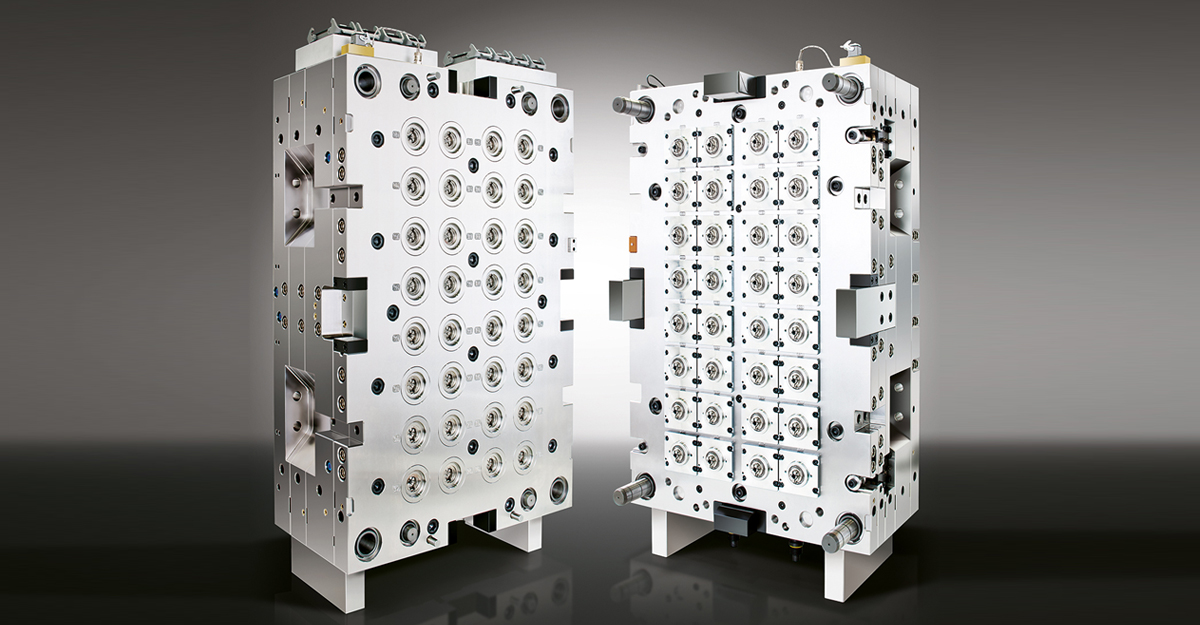

Semiconductor Packaging Mold Processing Division

Transfer molds in the multi-plunger design feature multiple resin-feeding pots, which significantly increases the effective utilization ratio of resin, reduces the molding cycle, and dramatically improves the molding quality.

We have dramatically improved our resin sealing technologies by developing compression molds following transfer molds in the multi-plunger design.

Compression molds manufactured with our ultra-precision processing technologies provide high-precision, high-quality products by minimizing damage in the molding of low-k materials, thinning wires, and even large substrates and wafers

Precision Injection Mold Processing Division

SENMAY SEIKO conducts business centered on the production of injection-molded products for precision plastic parts. With our years of accumulated experience, we have a complete in-house system from mold design, prototyping, mass production, printing, inspection and packaging, so we can provide customers with products with stable quality. Currently, SENMAY SEIKO is focusing on contract manufacturing of medical products, disposable medical device accessories, and care-related plastic products. We have obtained various certifications including ISO 13485 (Quality Management System for Medical Devices) to provide medical related products.In addition, products can be manufactured and assembled in a clean room.

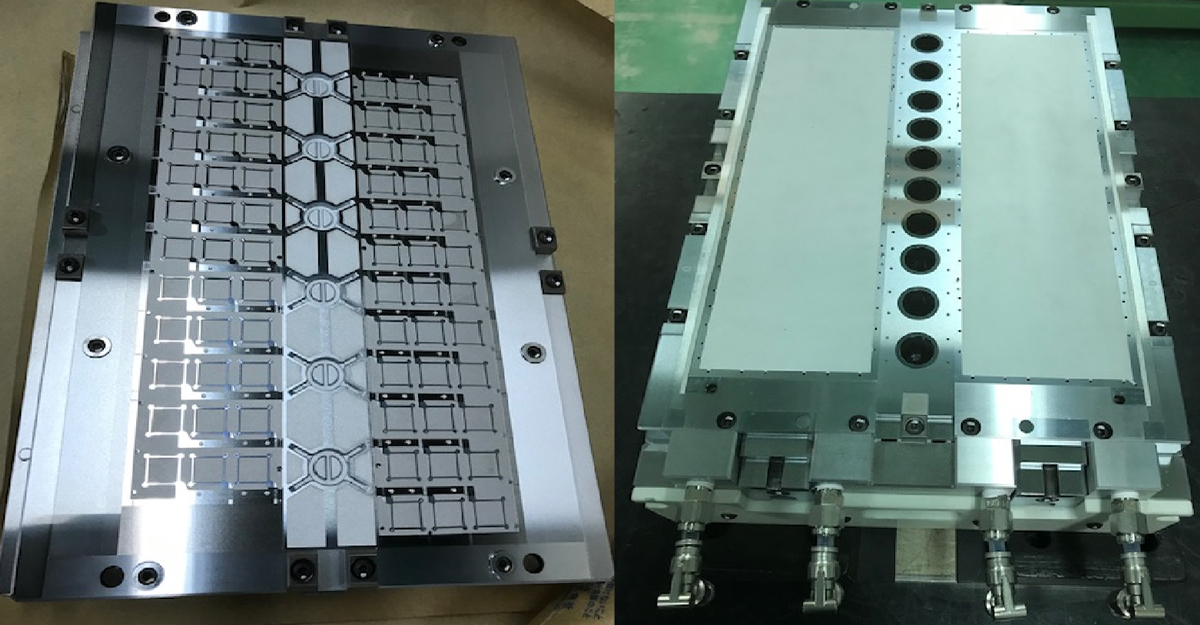

Precision Stamping Mold Processing Division

Senmay Seiko company's metal stamping die production standard: We can never provide metal die products in a state where we cannot guarantee (high precision, high quality and reliability are preconditions). Strict inspections are carried out throughout the manufacturing process. We always strive to maintain a certain level of quality (to deal with a machining accuracy of 0.001mm) in production. At the same time, based on the technical data and knowledge we have accumulated over the years, we are able to achieve ultra-precision and high-durability mold making correspondence. In the future, we will also pursue the actual production of more than 5800 molds so far.

Precision Parts Processing Division

As a manufacturer of ultra-precision molds, our company utilizes the experience in ultra-precision machining accumulated over many years, and has the ability of high-precision ultra-precision and fine machining to meet various needs of customers. On the basis of the core technology accumulated over the years, with the most advanced processing equipment and mature technology, the company realizes sub-micron processing of ultra-hard materials, which can not only produce semiconductor and LED molds, but also provide overall solutions for all precision processing. Program.

Ultra-Precision Optical Components Division

The company utilizes a fusion of precision lens manufacturing techniques, advanced production technologies, and high-precision lens manufacturing technologies to support their products. They have also developed opto-nanotechnology, which combines optical thin film deposition technology and ultra-precision metal machining technology, to create advanced products. They continuously strive to improve their unique technology and techniques, as well as their development capabilities and innovative ideas, to meet the high demands of the imaging and industrial industries for quality, cost, and delivery time. Their goal is to contribute to the development of the industry and create new value.

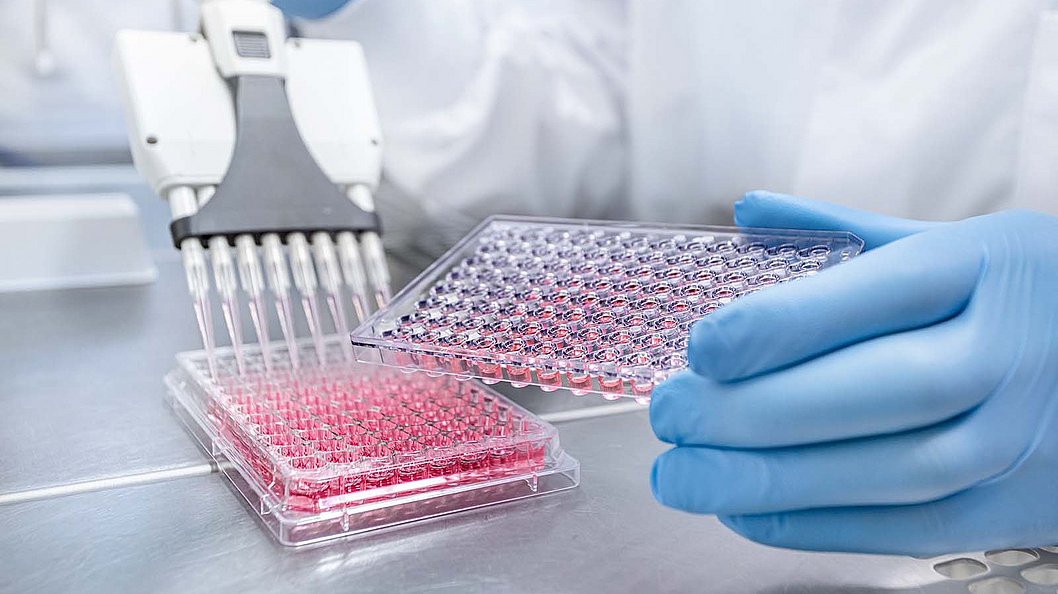

Medical Consumables Processing Division

We are fully committed to becoming your world-class, customer-focused CDMO partner in developing and delivering innovative solutions to enhance user experience. SENMAY Group of Companies is able to comprehensively support your specific needs in point-of-care diagnostic devices, in vitro diagnostic (IVD) consumables and medical solutions, thanks to our team of experts in development, injection molding, automated assembly and demonstration. As a one-stop service provider, our unique approach means we cover the entire product lifecycle, from concept definition to industrial delivery and final packaging, providing pharmaceutical and healthcare companies with unprecedented diagnostic solutions to accelerate time to market and Lower total cost of ownership.

Ultra-precision optical parts manufacturing plant