|

Quotation requests, business negotiations for optical components and mold manufacturing |

|

|

|

|

|

SENMAY has numerous specialists in optical systems who not only excel in high-precision manufacturing, but also listen to our customers' specifications (resolution, beam diameter, brightness, illumination uniformity, layout constraints, etc.) and requests, and provide optical design and proposals to meet their needs. Our semi-custom lenses, which leverage our accumulated experience and know-how over the years, aim to establish a pioneering position in the one-off lens scene both domestically and internationally by providing detailed customization tailored to our customers' circumstances from the design and prototyping stages. We also collaborate with our in-house processing and manufacturing departments to propose designs that consider productivity, tolerances, product materials, costs, and other aspects of manufacturing.

|

|

|

Design and manufacture of optical components. |

||||

|

|

||||

|

We propose the best solutions for the problems of our customers, whose solid technology and experience tell the story of history.

We design (lenses, mechanisms) from specification review to customer needs such as camera lens units, sensing lens units, lighting lens units, viewfinder units, etc. In addition, we have experience and know-how in designing optical systems used in various markets such as mobile, automotive, security, and medical fields. We will actively take on even the most difficult requests. Optical design is the most important process that determines the performance of optical components such as lenses and mirrors. Since customers have a wide variety of requests, commercially available optical design software cannot cover all of them. At our company, in order to maintain the required performance as a unit combined with other parts, as well as the high precision of the lens itself, we first set up a meeting to listen to the customer's consultation and requests. I'm here.

|

||||

|

|

||||

|

||||

|

*First, please let us know what kind of optical lens you are trying to achieve. If you already have a detailed specification sheet, please provide it to us. Even if you don't have one, please let us know how you plan to use it (imaging system/lighting system/sensor and signal system), the light source (manufacturer/model number, light distribution characteristics, emission surface area, etc.), the lens (size constraints, material, focal length, NA, effective diameter, etc.), the range of lens placement, the irradiation surface (position, size, light intensity distribution, etc.), and other restrictive conditions that you know. If there is a lack of information, we will conduct hearings through consultations.

*After listening to the specifications and requests for the optical lens, if we determine that it cannot be achieved optically, the cost will be high, or it will be difficult to commercialize when considering costs, yield, and productivity, we will consider it while hearing the priority order, such as specs and costs. After that, we will propose a plan from our company. Based on the feedback information from our customers, we understand their intentions, share ideas for feasible optical lenses, and shape them.

*Once the outline of the optical lens is settled, we will start the conceptual design. In the conceptual design, we will perform optical design using performance simulations and create system concept diagrams. Furthermore, we will devise measures to achieve the requested specs for issues that emerged during the advancement of the outline design. At this stage, it is possible to present an outline of the cost and product cost of the optical lens development.

*Based on the content presented in the outline design, for the imaging system lens, we will prioritize and determine the detailed specs of mainly the angle of view, resolution (image sensor selection, size), and F-number while hearing the priority order. For the lighting system lens, we will prioritize and determine the detailed specs primarily of the illumination distribution (uniformity, desired distribution shape), brightness (light source selection, efficiency target), and product size/shape while hearing the priority order. We will then reflect these specs in the optical design. Once the detailed specs have been confirmed with the customer, we will move on to the detailed design.

*In the detailed design, we first perform tolerance calculations to determine the tolerance necessary to ensure the overall performance of the optical system for each lens surface shape, thickness, eccentricity, etc. Next, we design the external shape of each lens, taking into account molding, and concurrently design the barrel and holder to satisfy the tolerance of each lens. |

||||

|

|

||||

|

||||

|

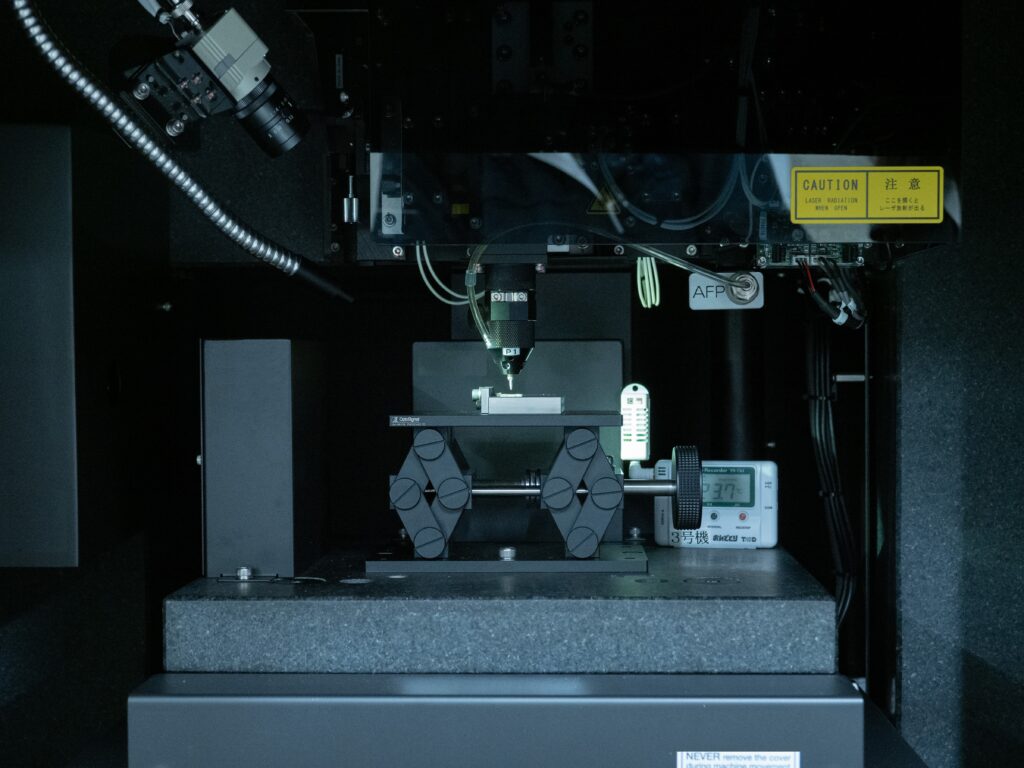

SENMAY manufactures refractive and diffractive optical elements using ultra-precision machining and lithography. They possess numerous ultra-high precision measuring instruments for evaluating machining accuracy and also develop correction techniques. SENMAY conducts joint research and development with machining equipment manufacturers and possesses cutting-edge equipment. They also put effort into establishing a machining environment, and have installed machining equipment in a building designed with considerations for precision machining. SENMAY is always striving for the evolution of mold machining technology and achieving the production of high-quality optical elements.

|

||||

|

|

||||

|

||||

|

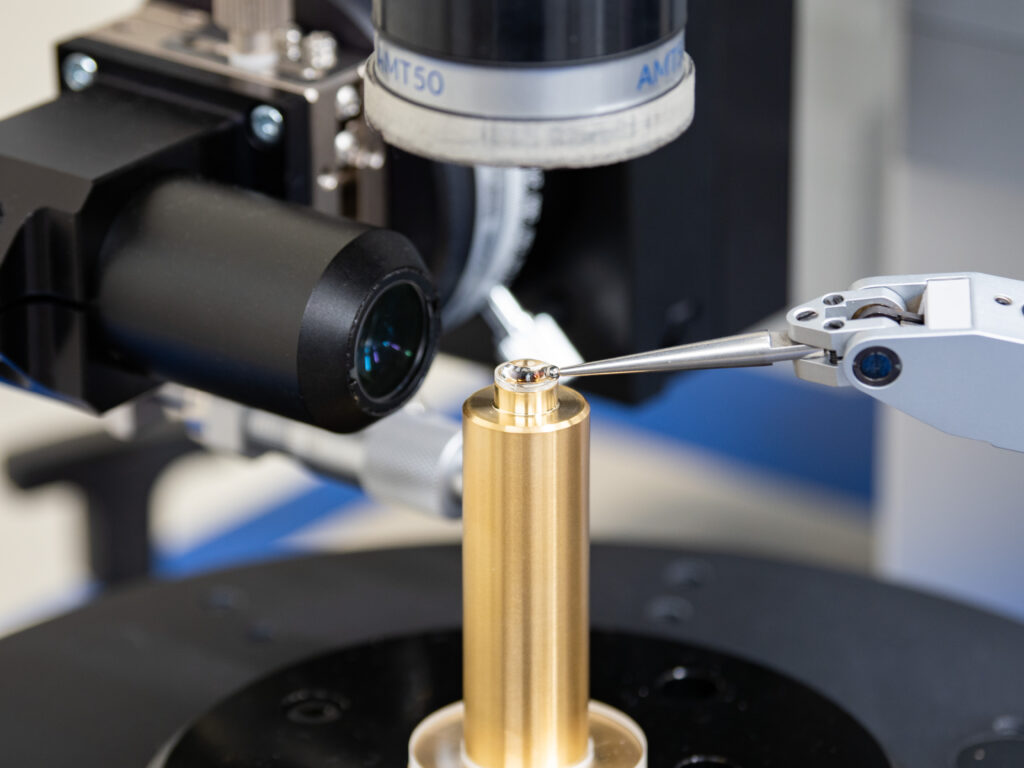

In order to achieve advanced manufacturing, we believe that advanced measurement and evaluation techniques to support the quality are also essential. SENMAY possesses various ultra-high precision shape measuring instruments, dimension measuring and evaluating machines, and also creates dedicated functional evaluation machines according to the necessary applications. This allows us to ensure quality assurance not only through shape and dimension evaluation, but also through "optical functionality" evaluation. Furthermore, SENMAY has obtained ISO9001 or IATF16949 at all production sites and has established a highly reliable management system. |

||||

Mass production processing, mold maintenance/maintenance |

|||||||||||||

|

|

|||||||||||||

|

|||||||||||||

|

Contract development and manufacturing of precision optical products (OEM) |

|||||||||||||

|

SENMAY possesses the necessary technology for high-precision production of optical components, including molded resin and glass parts. This allows us to meet the significantly higher precision requirements for optical components compared to general machine parts. We have established a stable production system using TPM, from lens design to molding, coating, and assembly, and by manufacturing domestically in our own factories, we thoroughly manage quality and provide high-quality products to our customers. Furthermore, we have gained trust from many customers due to our cost performance that leverages the characteristics of TPM.

|

|||||||||||||

|

|||||||||||||

|

Contract development ad manufacturing of AR-HUD products (OEM) |

|||||||||||||

|

The manufacturing technology for freeform optical components has become increasingly important with the proliferation of optical technologies such as AR, VR, and HUD. Conventional spherical and aspherical lenses cannot meet the optical quality and size requirements of products such as AR, VR, and HUD. Freeform optical components have excellent optical characteristics and can compensate for the shortcomings of conventional axially symmetric lenses. SENMAY has years of experience in the manufacturing technology of freeform optical components and has developed processes such as mold design, lens injection molding, and surface accuracy error compensation to ensure lens quality and shorten development time. Freeform optical components have complex shapes and require the integration of many technologies such as mold design, processing, injection molding, measurement, and surface accuracy error compensation.

|

|||||||||||||

|

|||||||||||||

Fully automatic assembly technology for precision optical lens modules |

||||||||||||||

|

|

||||||||||||||

|

|

||||||||||||||

|

We have automated numerous processes such as molding, assembly, evaluation, secondary processing, and packaging. Automation not only increases productivity by enabling unmanned 24-hour production, but also contributes to improving product quality by reducing repeatability and quality variation. We also develop evaluation equipment using AI and other software. These automated devices, including the software such as AI, are designed and manufactured in-house, leveraging our high production technology.

In order to carry out production with stable quality and on-time delivery, |

||||||||||||||

|

|

||||||||||||||

|

Optical thin film design/Vacuum deposition |

||||||||||||||

|

|

||||||||||||||

|

||||||||||||||

|

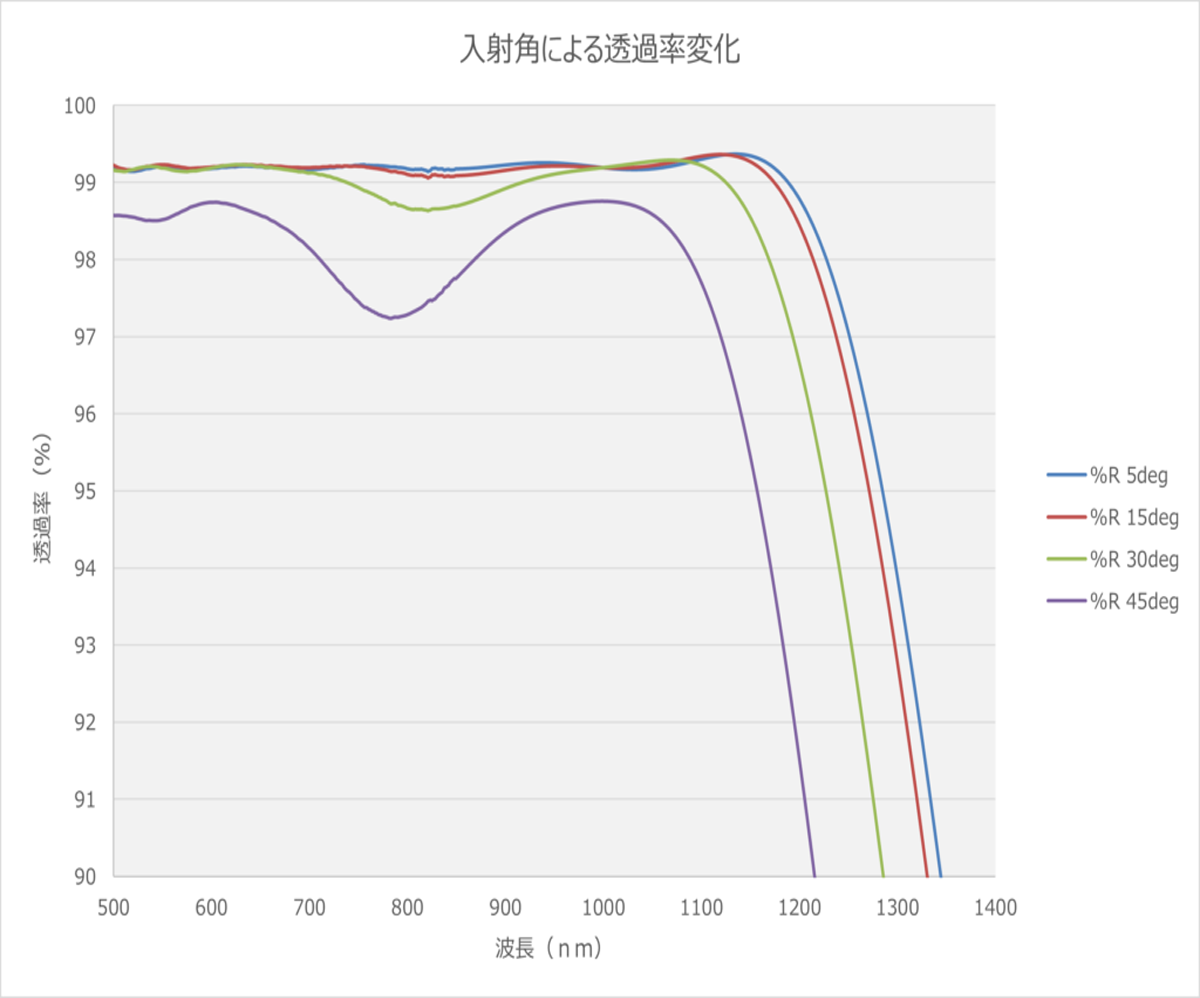

We are able to manufacture and design products using "thin film design and deposition technology". Deposition technology (vacuum deposition technology) is a technology that forms a thin film by evaporating materials in a vacuum. By controlling the thickness and number of layers of the thin film to control reflection and transmission of light using the property of thin films causing interference of light, we can obtain desired characteristics. We also accept requests for only deposition processing (prototyping and mass production), so please feel free to consult with us. |

||||||||||||||

|

||||||||||||||

|

|

||||||||||||||

|

Performance evaluation & reliability test |

||||||||||||||

|

|

||||||||||||||

|

||||||||||||||

|

To evaluate high-precision plastic lenses and precision molded products that require a precision higher than the accuracy required in the product, precise evaluation equipment with an accuracy higher than the accuracy required in the product is essential. SENMAY Co., Ltd. has established a solid evaluation system by utilizing laser microscopes, interferometers, shape measuring instruments, and ultra-high precision 3D measuring machines that can measure down to the nano level. In addition, we offer various reliability testing equipment, and can respond to various reliability tests such as high temperature, low temperature, high-temperature and high-humidity, and heat shock. |

||||||||||||||

|

||||||||||||||