|

Negotiation of inquiry and mold making |

|

|

|

|

|

"Business" is to let customers understand our strengths and technical capabilities, and undertakes the task of connecting various departments with customers.We will wholeheartedly respond to customer requests and needs, with the goal of achieving customer trust and continuing to accept orders.Dialogue with customers plays a very important role. Your contacts accompany you at every stage of the manufacturing process,And keep you up-to-date with regular presentations of project plans. The close link between our design and mold making departments creates synergies,Can bring you technical added value in the best way. Inspections and process steps are defined during the development phase.All molds are integrated with process analysis devices, so that we can identify process changes in the product formation stage, so as to take targeted countermeasures.In the case of designing and manufacturing related molds for the products that customers want to realize, and examining the most suitable "design plan" and "quality control method" - between overseas bases (direct input from our overseas bases to customer's overseas bases), it is also possible All negotiations can be done domestically. Being a partner means giving trust! Your trust in our knowledge determines our success. Entrust your future innovative ideas to a competent partner. |

|

|

Mold design . Processing .Fabrication |

||||

|

|

||||

|

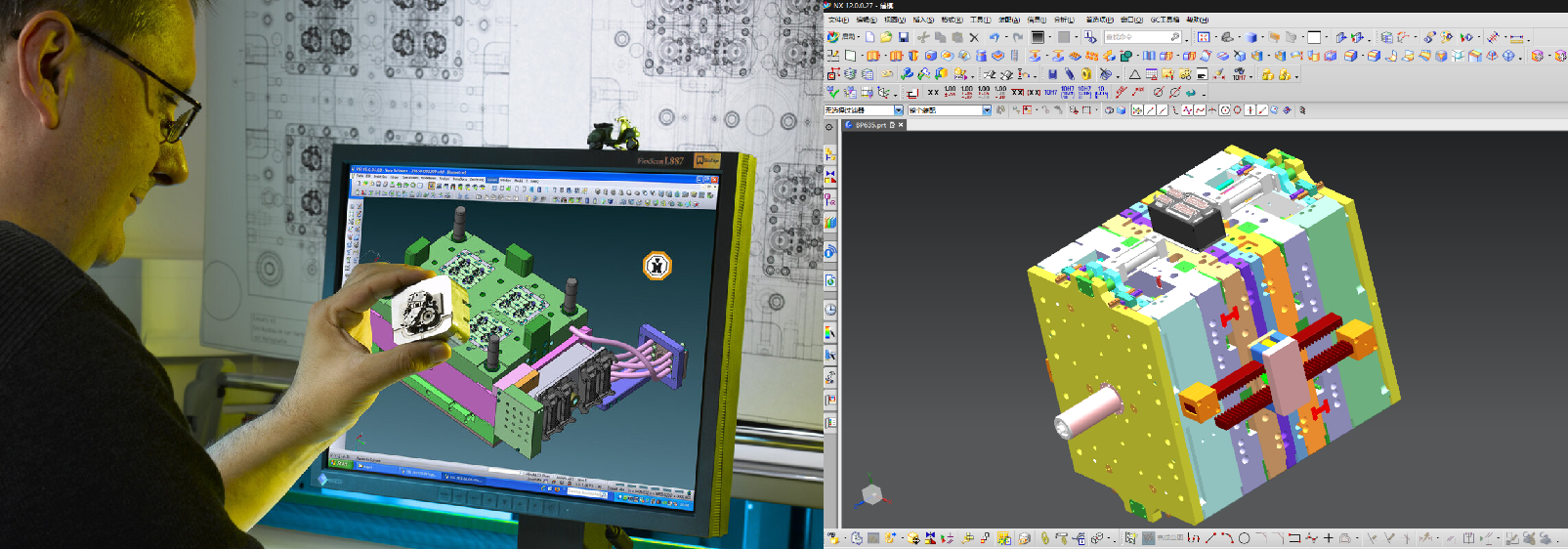

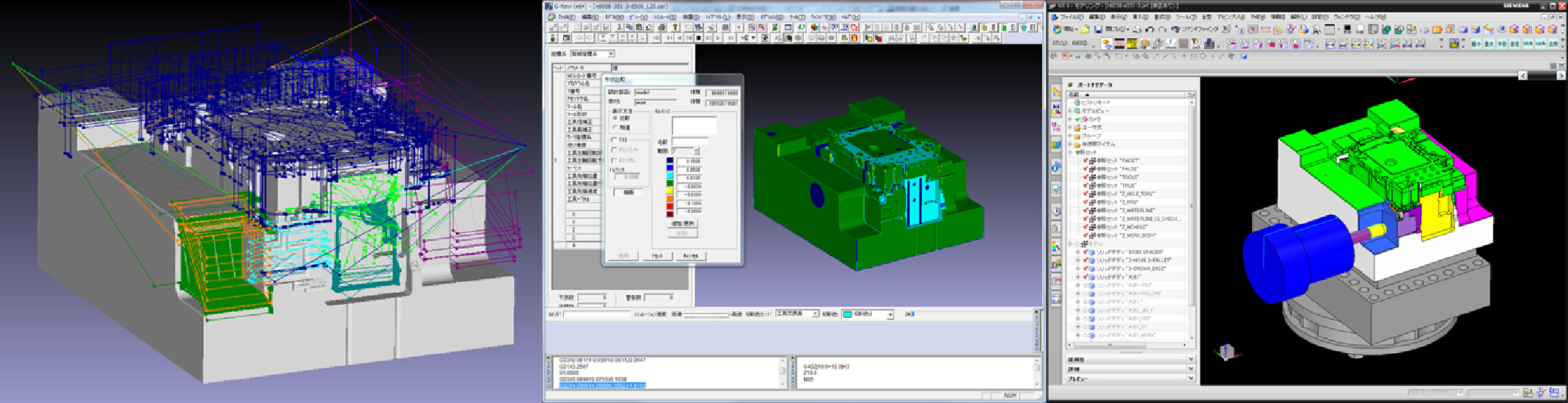

Mold designers with rich experience and practical results in the field of ultra-precision molds will listen to customers' opinions, put forward proposals to improve production technology, propose molds that increase yield and increase production efficiency, and design. For the mold design of precision molded products, it is necessary to repeatedly conduct various researches such as flow analysis and cooling techniques to meet the strict requirements of accuracy, production efficiency, durability, etc., flexible imagination and practical conception. Pursue efficient product manufacturing and quality assurance in the data management of a one-stop 3D system of mold design, program, simulation, actual processing, and measurement.

|

||||

|

|

||||

|

||||

|

* The experienced designers of our company conducted thorough specification negotiation on the product drawings to design molds that satisfy customers. * Make 3D models through NX CAD. * Through the flexibly use of various mold design support tools, rapid and highly advanced design is realized. |

||||

|

|

||||

|

||||

|

* Using proprietary 5-axis machining CAM to produce high-quality tool paths. * Machining tool path generation ~ simulation automation and thorough accident prevention system. * To produce high-quality products, please use micron μm. Our company requires the processing accuracy per unit, from room temperature management to the maintenance of processing machinery, to inspection of the environment, under a strict production management system, the latest equipment and skilled technology The fusion of high-quality products are provided to customers. * Starting from the mold drawing of the 3-dimensional design, the CAM operator will send high-precision data for each process at high speed on the company's internal LAN. From processing to electrode data, staff with processing theory and technology are responsible. |

||||

|

|

||||

|

||||

|

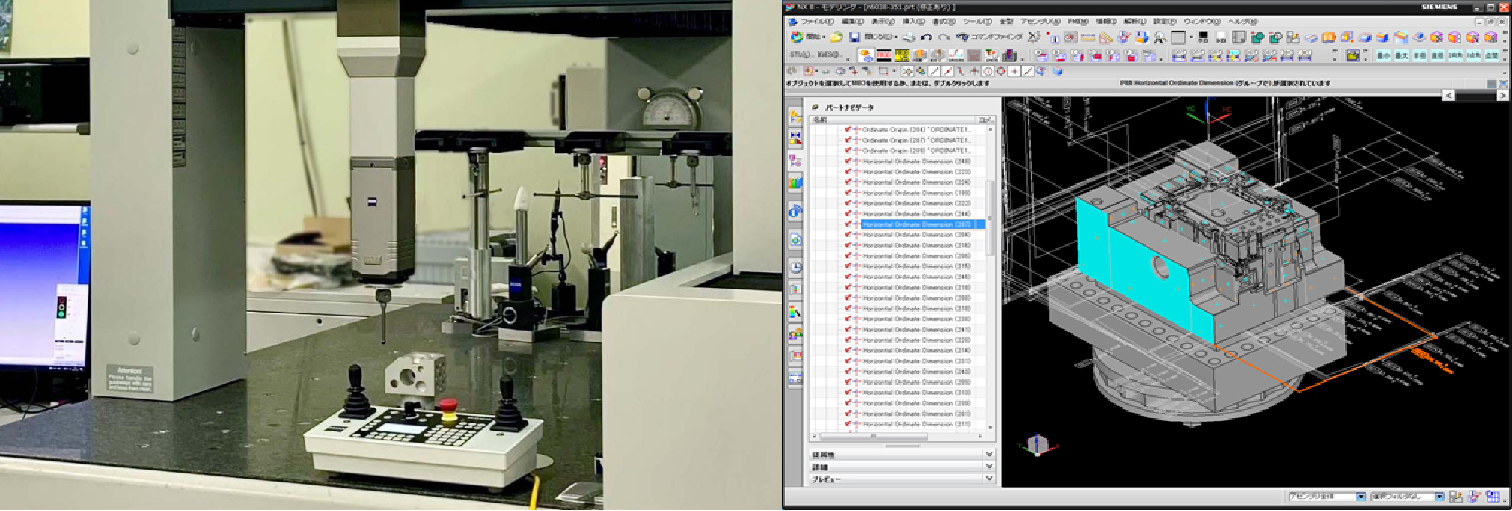

* Instructions for measuring points based on 3D models and production of safe measuring programs. * According to the linkage of the report of the measurement result and the 3D model, the visibility of the correction part can be known at a glance. * Use a high-precision measuring instrument to perform verification (measurement) of the sample that was tried. Even if it is outside the tolerance of a few microns, it will be re-adjusted and shipped in an acceptable state. Then, inform the guest whether the authentication data is qualified or not. |

||||

|

Mold assembly / commissioning |

|

|

|

|

|

The final process of the mold is a manual operation that cannot be mechanized. Assembly requires an accuracy of 1/1000mm unit. Feel the difference of 1/1000 of a millimeter with your fingertips,The assembly experience of mold parts is the most important job.According to the synergy with the mass production and product supply departments, the daily pursuit of molds that contribute to production can provide efficiency, maintainability,Failure-free molds from the customer's point of view. Most parts of precision molds require strict precision.Strict inspections are repeated in all stages of manufacturing. Sub-micron precision device, large-scale 3D measuring machine, also corresponding to complex shapes Advanced inspection equipment such as non-contact measuring machines are used by a full-time person in charge to check the accuracy of complex molds without spare effort.Assemble the parts confirmed in that way to the mold temporarily, and then carefully check the overall condition. Through repeated forming operations, the mold will be affected by high pressure and temperature,Various parts will deteriorate due to various reasons. Carry out appropriate maintenance to ensure the life of the mold and the quality of the molded product. |

|

|

Mass production / Mold maintenance |

|

|

|

|

Contract development and manufacturing (OEM) of precision connector products |

|

Senmay Seiko uses its own core injection molding mold technology, including the accumulation of assiduously studied technology and the latest processing equipment, which can realize the processing of 1μm to establish and produce high-precision products. Production planning...Grasp the status of the production process while sharing information with the machine operator, formulate the optimal production plan for the customer's order, and issue manufacturing instructions to each process. The finished product is managed by barcode and shipped according to the customer's delivery date. All of these are ITized, and the produced connectors become traceable. The following products and molds are representative products produced by our company. *Precision connectors related to various automobiles and production machines. *Board-to-board connectors (for smartphones, mobile terminals, etc.) *We have a track record of handling narrow pitch BtoB connector terminals with a pitch of 0.3mm.

|

|

|

Quality management |

|

|

|

|

|

*ISO13485 (Medical Devices and Drugs for In Vitro Diagnostics) We have obtained ISO13485 certification for the manufacture of medical devices and operate under a quality system that meets international standards. In addition, all factories implement quality management in compliance with ISO9001, striving to improve customer satisfaction. *With the continuous improvement of precision requirements, Senmay Seiko's molds have introduced high-precision measuring instruments to improve the efficiency of measurement operations, and strive to further strengthen and improve their measurement systems. In the industrial world where technological innovation is remarkable, molds with high precision and high durability are always required. This is because of our high-quality molds, which maintain micron-level precision even after millions of injection moldings, greatly helping to maintain and improve our customers' productivity. In order to meet such customer needs, Mori Seiko's molds are designed and manufactured, and high precision and high quality are always implemented and guaranteed. |

|