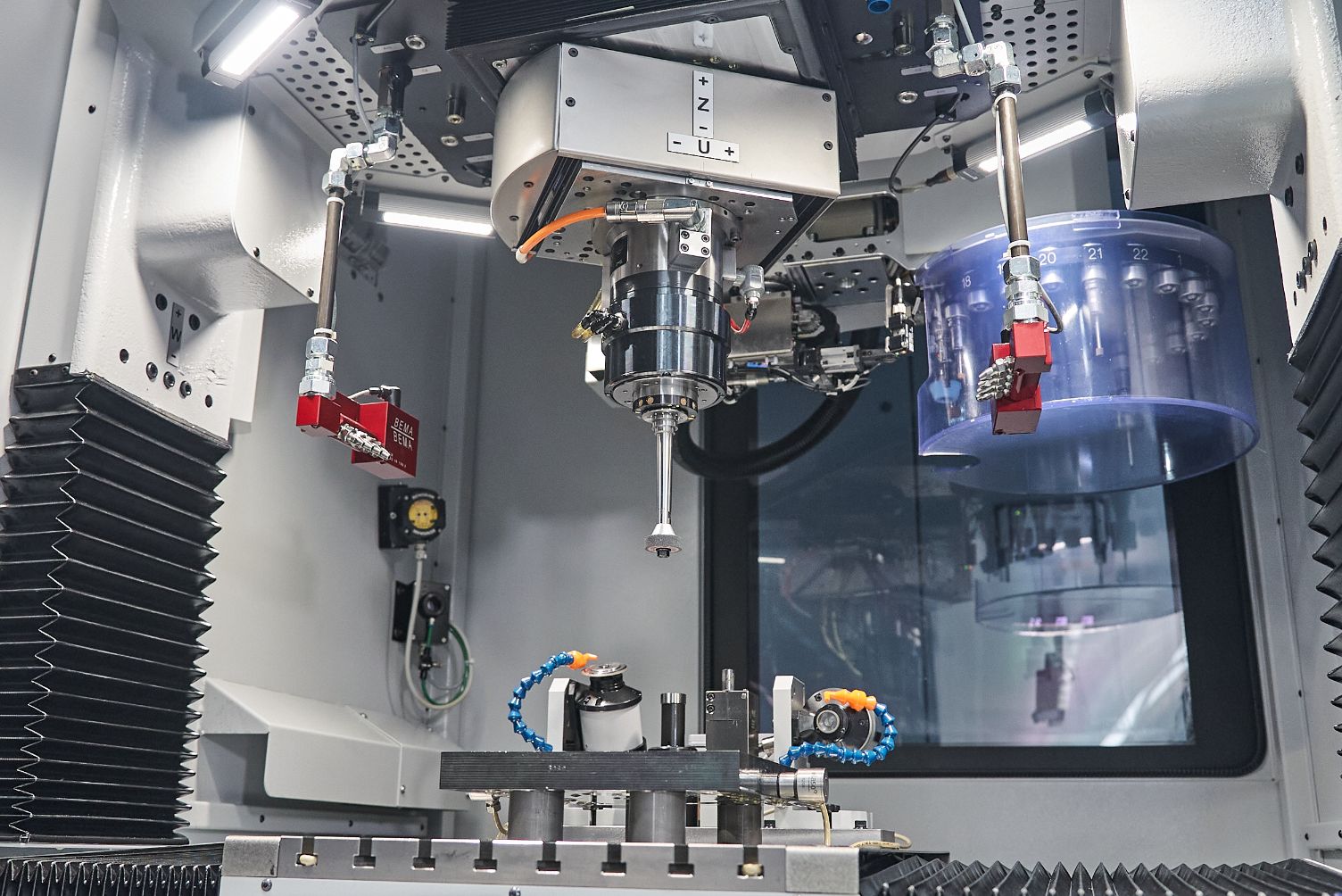

▼Ultra-precision CNC machining

|

|

|

|

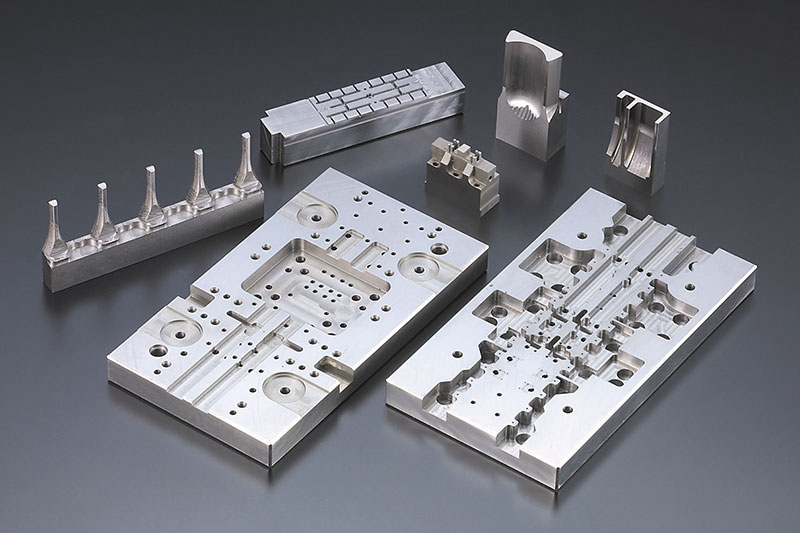

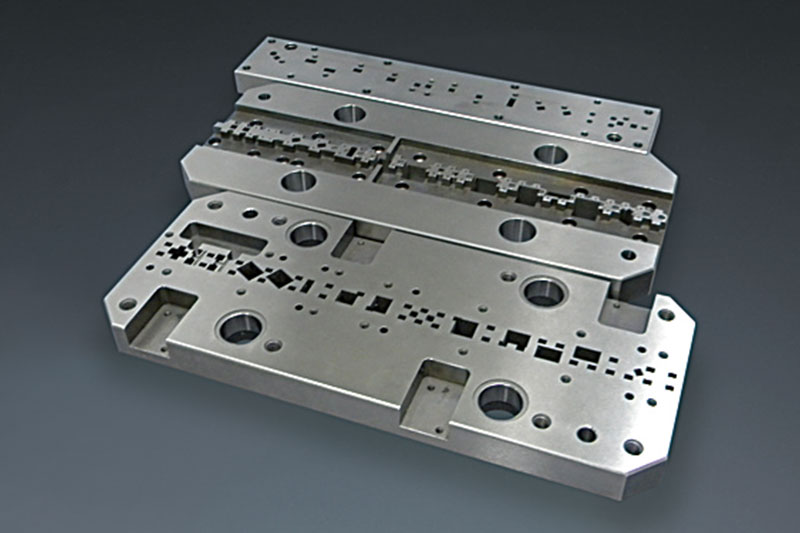

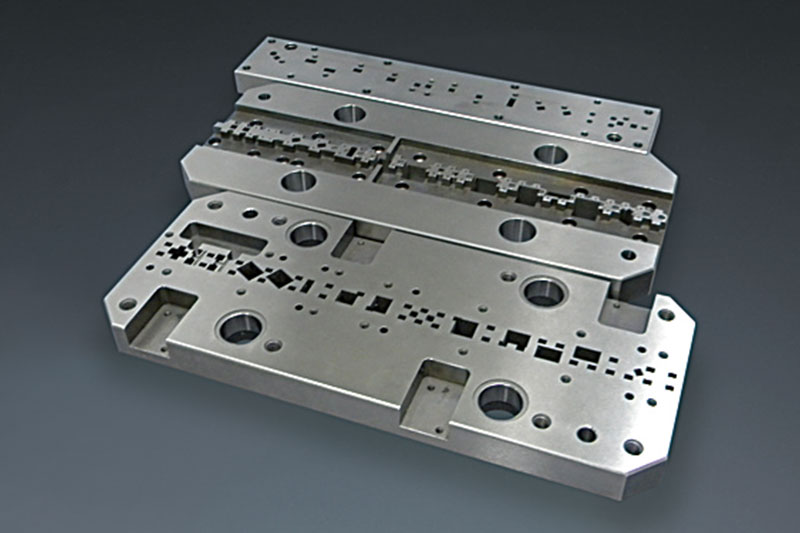

Using CAD/CAM, the tool steel such as DC53, HPM31, SKD11 and other tool steels are used as the center to process the mold plate and the micro-hole processing.

|

Centering on metal stamping dies and metal plate processing of injection molding dies, it carries out cutting processing of die parts such as punches, concave dies, front cavities, and rear cavities.

|

▼Micro precision machining

|

|

|

|

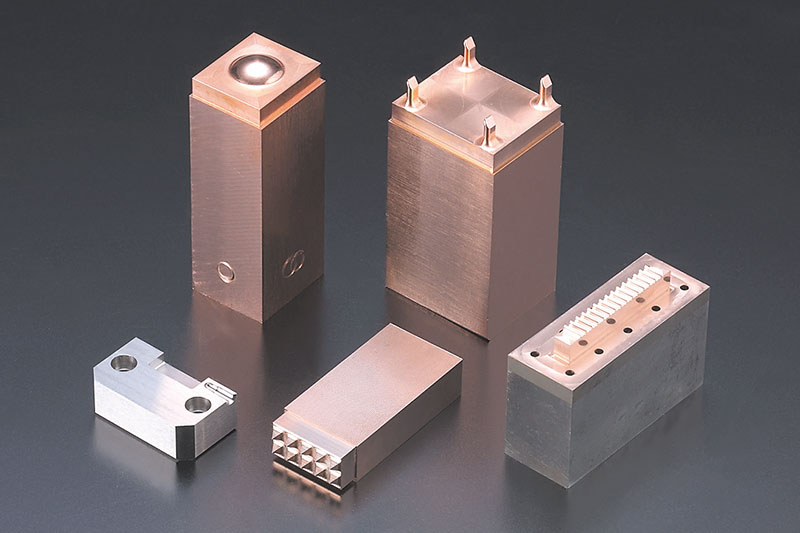

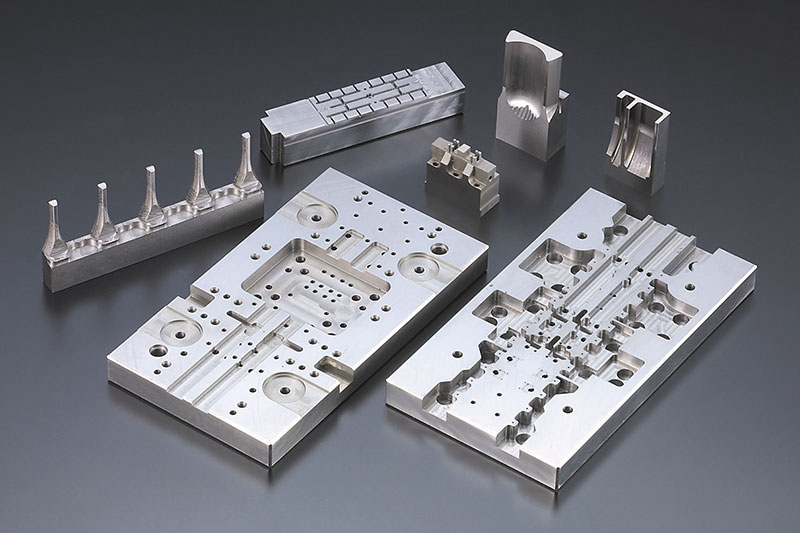

Electrodes for electric discharge machining and cutting work of heat-treated hardened materials are performed in the machining center.

|

High-speed cutting of electrodes for electric discharge machining. We also process integrated Thomson punches (engraving blades) that require strict cutting edge accuracy.

|

▼Surface grinding / forming grinding

|

|

|

|

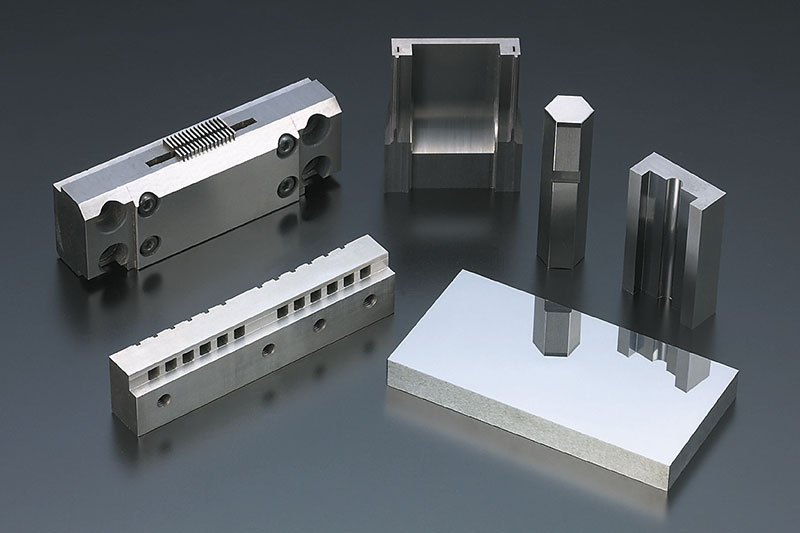

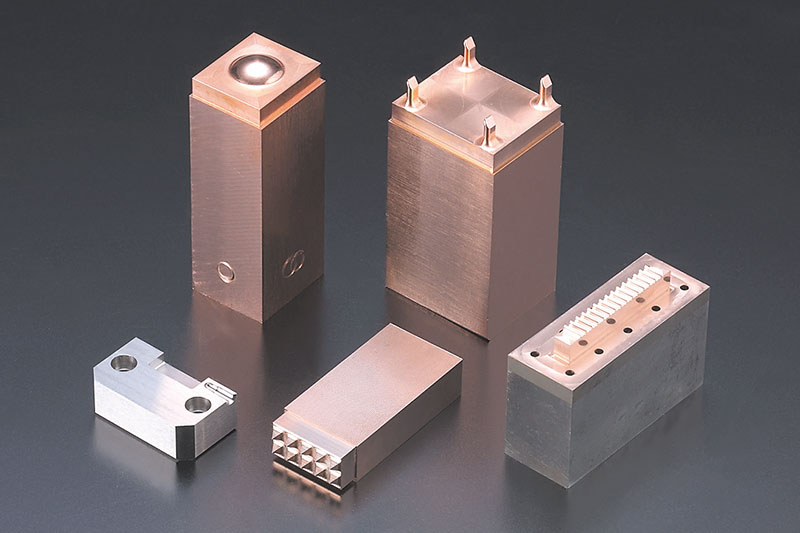

In addition to mirror grinding of flat surfaces and forming and grinding of plastic mold parts, we also perform vertical grain forming and grinding of press punches using the precision CNC forming and grinding machine Meister.

|

We grind high-hardness materials such as tool steel, cemented carbide, ceramics, and PCD (sintered diamond).

|

|

|

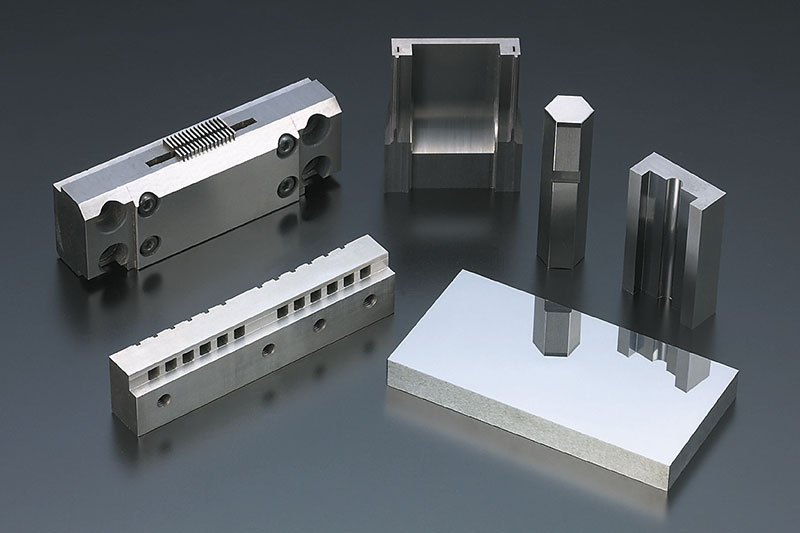

We grind fine parts such as punches and dies for connectors and lead frames.

|

The latest CNC profile grinding machine enables mirror profile grinding with a surface roughness Rz of 0.1μm or less. It is also possible to process the deformed part surface of plastic mold parts.

|

|

|

We pay the latest attention to the processing environment and also perform ultra-precision hole processing for aluminum die sets.

|

We perform plate hole processing and complicated contour shape processing of press dies with a CNC jig grinding machine.

|

|

|

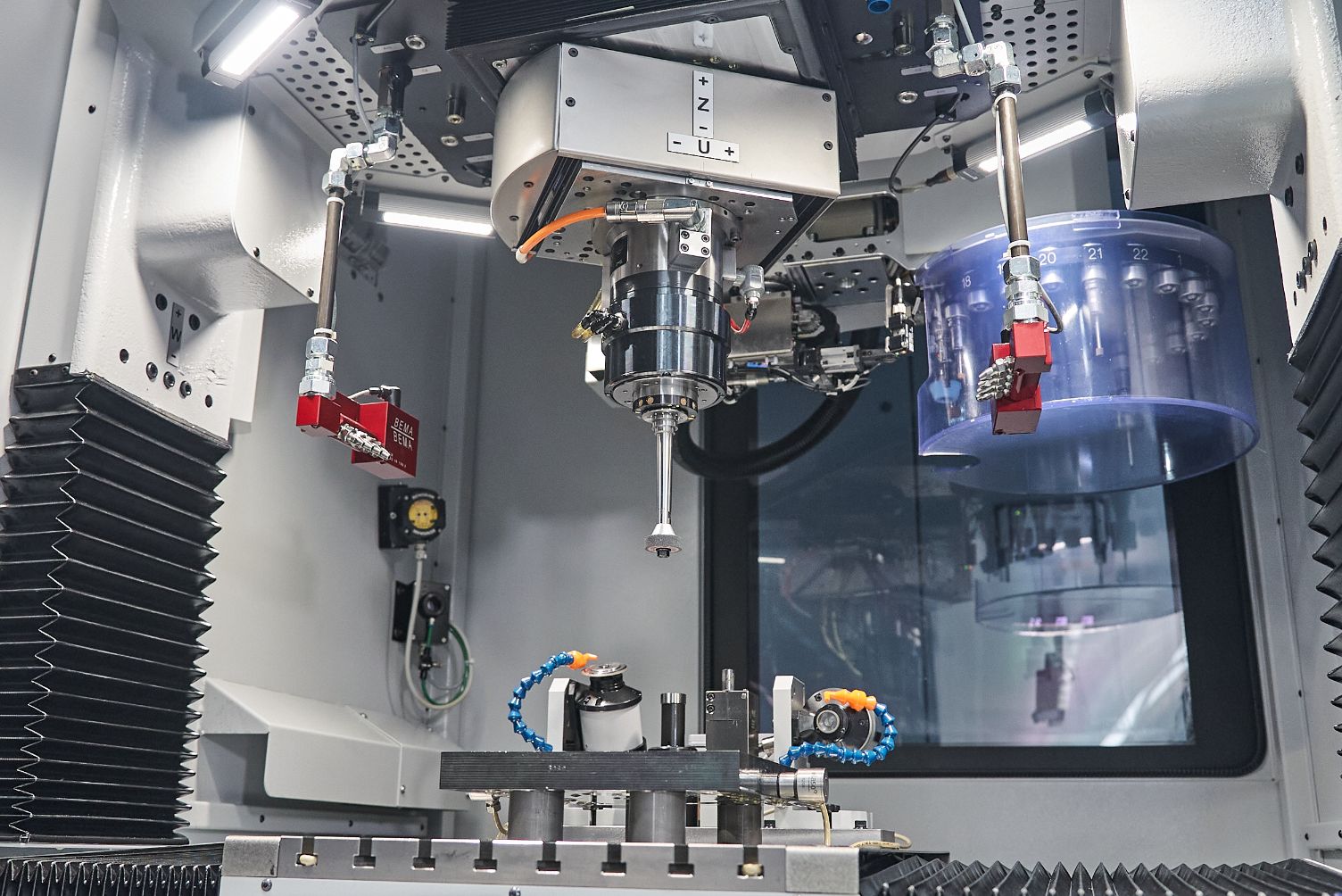

We have introduced many of the latest CNC die-sinking electric discharge machines to machine the fine cavity core, which is the heart of plastic mold dies.

|

We perform shape engraving of cavities and cores, reverse electric discharge machining of press punches, and small hole electric discharge machining.

|

|

|

High pitch accuracy is required for ultra-precision progressive press die processing. We perform wire cutting in a constant temperature precision processing room at ± 1 °C.

|

Widely used for die plate processing, punch dies, cavity cores, automatic machine parts, etc.

|